What is a Quality Management System (QMS)?

QMS stands for Quality Management System. A QMS is a formalized system that documents processes, procedures, and responsibilities for ensuring products or services consistently meet customer and regulatory requirements.

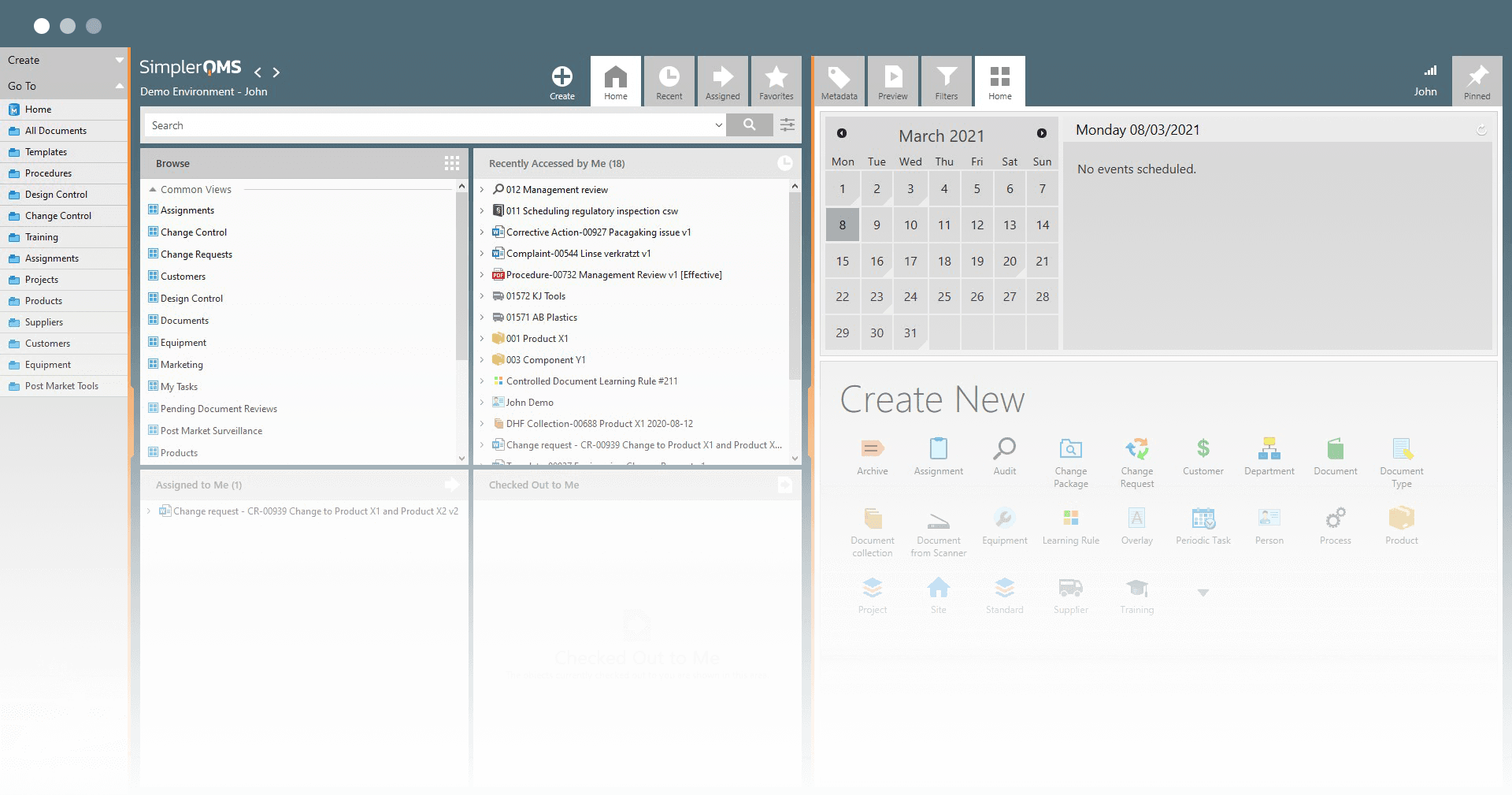

Discover how a modern QMS platform can streamline your quality management processes.

Book a demo to learn how an electronic QMS can improve quality and compliance in Life Science companies.

What is the Definition of Quality Management System (QMS)?

A Quality Management System (QMS) is a formalized system that documents processes, procedures, and responsibilities for achieving quality policies and objectives. A QMS ensures that products or services are consistently in compliance with customer and regulatory requirements. It achieves this by maintaining records of activities, which serve as evidence that quality-related tasks are being systematically performed.

A Quality management system encompasses the planning, quality control, quality assurance, and improvement of quality across various operations, aiming to enhance customer satisfaction and improve compliance with regulatory requirements.

An objective of a QMS is to manage a company’s activities to comply with customer and regulatory requirements while continuously improving effectiveness and efficiency through the systematic management of quality-related activities.

What Are the Different QMS Formats?

QMS can be implemented in various formats – electronic, paper-based, and hybrid, each catering to different organizational needs and preferences.

Below is an overview of the three primary QMS formats.

Electronic Quality Management System (eQMS)

Electronic Quality Management System (eQMS) refers to a digital solution designed to streamline and automate the quality management processes within a company.

The most common variations of the term “Electronic Quality Management System (eQMS)” are listed below.

- eQMS

- eQMS software

- QMS software

- Digital QMS

- Quality management software

An eQMS comprises a suite of QMS tools, which are essentially software modules and predefined workflows designed to automate and streamline specific quality management processes.

QMS software typically integrates various quality management elements, such as document control, change control, training management, corrective and preventive actions (CAPA) management, audit management, supplier management, and many others.

SimplerQMS offers comprehensive eQMS software tailored to the unique needs of Life Science companies. Book a demo with our Quality Solution consultants to learn more.

Paper-Based QMS

Paper-based QMS relies on physical documents for recording and tracking quality-related information.

Paper-based QMS offers simplicity and physical documentation and may be more cost-effective and accessible for some smaller companies. However, for larger companies, paper-based QMS can be less cost-effective in document control, scalability, and efficiency.

Hybrid QMS (Paper-Based and Electronic QMS)

Hybrid QMS combines elements of both paper-based and electronic systems in its framework for managing quality management processes.

In the hybrid QMS system, certain quality management processes and documentation are maintained in traditional, physical formats, while others use electronic tools and technologies.

Hybrid QMS allows companies to benefit from the familiarity of paper-based systems while incorporating the advantages of digital tools.

This hybrid strategy balances innovation with tradition, offering flexibility but risking inefficiency and data inconsistency in managing dual systems.

Why is Quality Management System (QMS) Important?

A Quality Management System is a requirement in several regulations, standards, and guidelines across multiple industries.

A QMS supports companies in achieving and maintaining compliance with customer and regulatory requirements. It ensures a company consistently delivers uniform and high-quality products or services.

By creating and implementing a QMS, companies gain multiple benefits, such as improving efficiency, ensuring compliance, reducing waste, decreasing costs, enhancing customer satisfaction, and ultimately achieving business growth and success.

What are the Benefits of Quality Management Systems?

The benefits that Quality Management Systems give companies result in more efficient, cost-effective, and safe processes.

The main benefits of QMS are listed below.

Improved Regulatory Compliance: QMS ensures that companies adhere to industry regulations, standards, and guidelines, reducing the risk of non-compliance and associated legal consequences.

Improved Customer Retention and Satisfaction: QMS enhances customer satisfaction by consistently delivering uniform and high-quality products or services, fostering loyalty, and increasing the likelihood of repeat business.

Promoted Continuous Improvement: QMS encourages a culture of continuous improvement, empowering companies to identify areas for improvement, implement changes, and optimize processes over time.

Developed Operational Consistency: QMS establishes standardized processes, leading to consistent and reliable outcomes, reducing variability, and ensuring a uniform approach across operations.

Enhanced Internal Communications: QMS promotes effective communication within the company, ensuring that all stakeholders are well-informed, leading to improved collaboration and teamwork.

Streamlined Employee Training: QMS provides a structured framework for employee training, ensuring that staff members are adequately trained and qualified to perform their roles efficiently.

Increased Efficiency and Reduced Waste: QMS identifies and eliminates inefficiencies, resulting in streamlined processes, reduced waste, and optimized resource utilization, ultimately contributing to cost savings.

Improved Decision-Making: QMS facilitates data-driven decision-making by providing insights into processes and performance, enabling informed and strategic decision-making at all levels.

Improved Company Culture: QMS fosters a culture of quality, accountability, and continuous improvement, creating a positive work environment and aligning employees with organizational goals.

Increased Profits: QMS contributes to increased profitability through improved efficiency, customer satisfaction, and reduced costs, positioning companies for sustainable growth and financial success.

What are the Different Types of Quality Management Systems?

There are various types of Quality Management Systems, each tailored to the specific needs and requirements of the implementing company. The nature of a QMS depends significantly on the industry in which the company operates and the applicable regulatory and customer requirements.

What are the Types of QMS for Different Industries?

Different industries have specific quality requirements that their QMS needs to reflect. The types of QMS implemented across various industries are further described below.

Life Science Quality Management System

A Life Science QMS is a formalized system tailored to document processes, procedures, and responsibilities specifically for the Life Science industry.

The objective of a Life Science QMS is to ensure that products and services in the Life Science sector consistently comply with regulatory and customer requirements regarding quality, safety, and efficacy.

Pharmaceutical Quality Management System

A Pharmaceutical QMS is a structured system designed to manage organizational processes, documentation, responsibilities, and procedures within a pharmaceutical company.

The aim of a Pharmaceutical QMS is to ensure product quality and safety throughout the pharmaceutical manufacturing process in compliance with regulatory requirements, such as Good Manufacturing Practices (GMP).

Medical Device Quality Management System

A Medical Device QMS is a formalized system designed to document the policies, procedures, and processes implemented by a medical device manufacturer to guarantee the safety and effectiveness of their product’s intended use throughout its lifecycle.

The Medical Device QMS goal is to ensure the safety and effectiveness of medical devices throughout their lifecycle, from design and development to manufacturing, distribution, and end-use.

Laboratory Quality Management System

A Laboratory QMS is a structured framework tailored to document processes, procedures, and responsibilities within laboratory settings, ensuring that testing, analysis, and research activities are consistently accurate and reliable.

The objective of a Laboratory QMS is to ensure accurate and reliable test results, maintain data integrity, and achieve compliance with customer and regulatory requirements.

Clinical Quality Management System

A Clinical QMS is a formalized system designed to manage processes, procedures, and responsibilities within clinical research, clinical trials, and healthcare settings, ensuring clinical trials’ quality, integrity, and safety.

Clinical QMS is often integrated into the broader QMS of pharmaceutical and medical device companies. This integration is essential because clinical trials are a critical component in the development and approval process for both pharmaceutical drugs and medical devices.

The Clinical QMS goal is to ensure patient safety, data integrity, and compliance with customer and regulatory requirements throughout the clinical trial process and healthcare delivery.

Food and Beverage Quality Management System

A Food and Beverage Quality Management System is a structured system to document procedures, processes, and responsibilities designed to ensure food and beverage products’ consistent quality and safety throughout the entire supply chain.

The objective of Food and Beverage QMS is to ensure the uniform and high quality of products from farm or source to processing, manufacturing, packaging, and distribution in compliance with customer and regulatory requirements.

Automotive Quality Management System

An Automotive Quality Management System is a structured system designed to document processes, procedures, and responsibilities within the automotive industry. It ensures that vehicles and automotive components maintain quality, safety, and reliability.

The aim of an Automotive QMS is to establish and maintain processes that guarantee the quality, safety, and performance of automotive products in compliance with customer and regulatory requirements.

Aviation, Space, and Defense Quality Management System

An Aviation, Space, and Defense Quality Management System is a formalized system to manage policies, processes, and documentation implemented within the aerospace and defense industry.

The goal of an Aviation, Space, and Defense QMS is to ensure customer and regulatory compliance with requirements regarding the safety of aircraft, spacecraft, weapons systems, and related products.

What are the Different Requirements for Quality Management Systems?

Different quality management standards, regulations, and guidelines outline the specific requirements for QMS. Some of these QMS requirements are industry-specific, while others serve as more general-purpose frameworks applicable across various industries.

Examples of the requirements for QMS are described below.

ISO 9001:2015

The ISO 9001:2015 standard establishes the general requirements for the quality management systems.

ISO 9001:2015 is a wide-ranging standard and is applicable across various industries. Moreover, the ISO 9001 standard is frequently utilized by pharmaceutical companies to outline the requirements for their QMS.

ISO 13485:2016

The ISO 13485:2016 standard outlines the requirements for a Quality Management System in the manufacturing of medical devices.

The ISO 13485:2016 compliant QMS provides a framework that enables companies involved in the design, development, production, installation, and servicing of medical devices to deliver safe and effective products consistently.

FDA 21 CFR Part 820

The FDA 21 CFR Part 820 is a regulation, specifically known as the Medical Device Quality System Regulation (QSR), established by the United States Food and Drug Administration (FDA).

The FDA 21 CFR Part 820 QSR specifies the Current Good Manufacturing Practices (cGMP) requirements for medical devices.

FDA 21 CFR Part 820 applies to medical device manufacturers who intend to distribute medical devices in the United States commercially.

ISO 15189:2022

The ISO 15189:2022 standard specifies the requirements for quality and competence in medical laboratories, including requirements for the quality system.

The ISO 15189:2022 applies to medical laboratories, ensuring the accuracy, reliability, and quality of laboratory services, ultimately contributing to patient safety and well-being.

ISO 17025:2017

The ISO 17025:2017 standard specifies the general requirements for laboratories’ competence, impartiality, and consistent operations. The ISO 17025:2017 standard outlines the requirements for the management system and related documentation.

ISO 17025:2017 applies to testing and calibration laboratories performing a wide range of analyses or measurements. Laboratories following the ISO standard can encompass a range of fields, including those within the Life Sciences.

ICH Q10

The ICH Q10 guideline establishes the requirements for the Pharmaceutical Quality System (PQS). ICH Q10 describes one comprehensive model for an effective pharmaceutical quality system.

The ICH Q10 PQS applies to the pharmaceutical and biopharmaceutical companies involved in the development and manufacture of drug substances (APIs) and drug products.

What are the Different Approaches and Methodologies of QMS?

Quality Management Systems encompass various approaches and methodologies that companies can adopt to manage their quality processes. Multiple QMS approaches and methodologies may be utilized, either in full or partially, depending on the company’s specific requirements and needs.

Some of the different approaches and methodologies are as follows.

Continuous Quality Improvement (CQI)

Continuous Quality Improvement (CQI) is an approach to consistently identify areas for improvement and implement changes to improve efficiency, effectiveness, and customer satisfaction.

CQI applies across various industries and is particularly beneficial in sectors where ongoing optimization is essential for meeting evolving regulatory and customer requirements.

While CQI is not mandatory, it is widely recognized as a best practice for companies aiming to foster a culture of continuous learning and improvement.

Total Quality Management (TQM)

Total Quality Management (TQM) is a quality management approach to achieve continuous improvement in the quality of products, services, and processes.

TQM involves the active participation of all employees throughout all company departments, emphasizing teamwork and a commitment to excellence. It applies to various industries and sectors, focusing on creating a culture of quality and continuous improvement.

Although not mandatory, TQM is often used when companies seek a comprehensive and holistic strategy to improve their processes and outcomes.

Lean Manufacturing

Lean Manufacturing is a production methodology focused on minimizing waste and maximizing efficiency. Lean Manufacturing principles are often used when companies aim for a more efficient and cost-effective production system.

The purpose of Lean Manufacturing is to eliminate non-value-added activities, reduce lead times, and enhance overall productivity. Lean Manufacturing applies to manufacturing industries, such as automotive and electronics, where companies seek to streamline operations and improve resource utilization.

While not mandatory, many organizations voluntarily adopt Lean Manufacturing to improve competitiveness and customer satisfaction.

Six Sigma

Six Sigma is a methodology that uses data management and statistical techniques to identify and eliminate defects in processes. Six Sigma follows a DMAIC cycle (Define, Measure, Analyze, Improve, Control) for continuous improvement.

Six Sigma aims to reduce defects and waste, ultimately improving process efficiency and quality.

Six Sigma is not mandatory and can be applied by any company that seeks to improve quality and reduce errors, particularly in manufacturing.

Six Sigma and Lean Manufacturing often complement each other, with companies integrating principles from both methodologies to achieve synergistic benefits.

Agile Quality Management

Agile Quality Management is an approach ideal for projects requiring flexibility and adaptation to changing requirements.

Agile Quality Management aims to foster flexibility, collaboration, and adaptability in delivering uniform and high-quality products or services.

While Agile Quality Management is not mandatory, many companies implement the approach to respond more effectively to changing requirements and deliver products or services that better meet customer needs.

What are the Core Elements of a Quality Management System (QMS)?

A Quality Management System consists of several core elements or modules that work together to ensure that a company’s products or services consistently comply with regulatory and customer requirements.

A QMS should reflect the specific processes and requirements applicable to a company and the industry in which it operates. Some components of a QMS are required by standards, regulations, and guidelines, while others are optional.

Some of the core elements of a QMS are further described below.

Document Control

Document control ensures that all quality-related documents and records are controlled, accessible, and up-to-date.

Document control encompasses both document and record, ensuring that relevant documentation, such as policies, procedures, work instructions, and specifications, are created, reviewed, approved, updated, and retired as necessary.

By establishing robust document control procedures, companies can mitigate the risk of errors, inconsistencies, and outdated information. Additionally, effective document management facilitates transparency, accountability, and traceability.

Change Management

Change management is the systematic approach to implementing new initiatives and modifying processes, products, documents, and workflows within a company. Change management ensures that any alterations made to the quality processes are carefully evaluated to minimize risks and maximize benefits.

Change management is an essential component of a QMS as it enables companies to adapt to evolving regulatory and customer requirements while safeguarding quality and compliance.

Training Management

Training management ensures that employees possess the necessary skills and knowledge to perform their jobs effectively and contribute to achieving quality objectives.

By providing comprehensive training programs, companies ensure employees understand their roles, responsibilities, and requirements of a QMS. Training management helps to minimize errors and improve productivity.

Deviation and Nonconformance Management

Deviation and nonconformance management is the systematic process of identifying, documenting, investigating, resolving, and preventing deviations or nonconformances related to procedures, products, suppliers, etc.

For example, a supplier delivered fewer items than expected, or equipment calibration is overdue.

Deviation and nonconformance management ensure product quality, patient safety, and regulatory compliance. When deviations or nonconformities occur, it is essential to address them promptly and effectively to prevent recurrence, minimize the impact on product quality and safety, and ensure continuous improvements.

Complaint Management

Complaint management is the formal process for receiving, recording, investigating, and resolving customer complaints. Complaint management enables companies to respond effectively to customer feedback, address quality issues, and drive continuous improvement.

By prioritizing customer satisfaction and actively engaging with customer complaints, companies can build trust, loyalty, and long-term relationships with their customers while maintaining compliance with regulatory requirements.

CAPA Management

Corrective Action and Preventive Action (CAPA) management establishes a formal process for identifying, investigating, and addressing problems and preventing the occurrence of similar issues.

CAPA management helps with identifying, addressing, and preventing non-conformities and deviations. By implementing effective CAPA processes, companies can minimize risks, improve processes, and ensure continuous improvement.

Equipment Management

Equipment management involves the registration, qualification, calibration, maintenance, and disposal of equipment used in the manufacture of products.

Equipment management focuses on establishing a systematic approach to ensuring the ongoing functionality, accuracy, and reliability of all equipment used within the companies’ processes. Properly managed equipment ensures that manufacturing processes are conducted accurately and consistently, minimizing the risk of defects or deviations from quality specifications.

Supplier Management

Supplier management involves the evaluation, selection, and monitoring of suppliers to ensure that they consistently deliver uniform and high-quality products or services.

Effective supplier management helps companies identify reliable and capable suppliers, optimize supply chain performance, and mitigate risks associated with poor supplier performance.

Risk Management

Risk management involves the identification, assessment, mitigation, and monitoring of risks that could impact product quality, safety, or compliance with regulatory requirements.

By proactively identifying and assessing risks, companies can implement strategies to mitigate or eliminate risks, thereby reducing the likelihood of quality incidents like nonconformance and deviations.

Audit and Inspection Management

Audit and inspection management is the systematic planning, execution, and follow-up of audits and inspections to assess compliance with internal policies, procedures, quality standards, industry guidelines, and regulatory requirements.

Audit and inspection management provides assurance that quality management processes are effectively implemented and followed throughout the company.

What is the Quality Management System (QMS) Documentation Structure?

Quality Management System documentation is the Quality Manual that defines a company’s quality system. QMS documentation includes policies, procedures, work instructions, records, and other relevant documents.

QMS documentation structure is a hierarchical organization of documents. The document hierarchy facilitates comprehension, communication, and visualization of the documentation structure.

The four levels of documents in a QMS pyramid are described below.

- Quality Policy: The quality policy is a high-level statement outlining a company’s commitment to quality. The quality policy sets the overall direction for quality efforts and serves as a guiding principle for employees.

- Procedures: Procedures outline the step-by-step methods or processes for performing specific tasks or activities. Procedures serve to standardize operations, ensure consistency, and facilitate compliance with regulatory requirements.

- Work Instructions: Work instructions provide detailed guidelines for completing specific tasks or operations, often at a more granular level than procedures. Work instructions are used to ensure that tasks are performed correctly, safely, and efficiently.

- Records: Records document the results, activities, or events related to quality management processes, such as audits and training. Records serve as evidence of performance and compliance, enabling traceability and accountability.

What is Quality Management Software?

Quality management software is a digital platform designed to streamline and automate quality management processes within a company.

Quality management software is used to streamline and automate quality management processes and help ensure compliance with standards, guidelines, and regulations. QMS software enables the systematic control of quality policies, procedures, and documentation, facilitating compliance with applicable requirements.

Adopting quality management software enables companies to implement an electronic QMS (eQMS), often referring to the software itself. Electronic QMS streamlines processes, including document control, change management, training management, audit management, nonconformance and deviation management, CAPA management, supplier management, and others.

Who is Quality Management System Software For?

Quality management system software is designed for all companies seeking to streamline and automate quality management processes, improve efficiency, and ensure compliance with regulatory and customer requirements.

QMS software is particularly valuable for highly regulated industries, such as Life Sciences, where compliance with specific regulations, standards, and guidelines is essential for operational success and patient safety.

SimplerQMS provides electronic QMS tailored specifically for Life Science companies. Our QMS software is designed to address the complex quality management needs in the pharmaceuticals, biotechnology, medical devices, CRO, CDMO, and other Life Science industries.

What are the Benefits of Using Electronic QMS?

The main benefits of using QMS software are listed below.

- Improved Compliance: QMS software helps companies comply with regulatory and customer requirements. The software’s predefined workflows ensure processes are being correctly followed. All actions in the workflow are automatically documented in a time-stamped audit trail.

- Enhanced Efficiency: Quality management software automates and streamlines quality management processes, reducing manual effort and minimizing errors. The implementation of QMS software leads to increased productivity and operational efficiency within the company.

- Increased Transparency: QMS software provides real-time visibility into quality management activities, allowing employees to access relevant data. Transparency fosters accountability, facilitates collaboration, and promotes informed decision-making.

- Cost Savings: QMS software reduces the need for manual paperwork, streamlines processes, and helps prevent non-value-adding tasks. As a result, companies can achieve cost savings through improved efficiency, reduced waste, and decreased risk of noncompliance.

We designed a QMS software business case template to assist you in assessing the value of implementing a modern QMS software solution and presenting it to your management.

The template is tailored to help you visualize the specific benefits that cloud-based QMS software can bring to your business, including potential efficiency enhancements, cost reductions, and improvements in compliance.

Assess the benefits of investing in an eQMS solution for your company by downloading our QMS Software Business Case template.

What Benefits Cloud-Based QMS Offers Compared to an On-Premise Solution?

The main benefits that cloud-based QMS software offers when compared to an on-premise QMS solution are listed below.

- Work From Anywhere: A cloud-based QMS stores data centrally and is accessible from anywhere with an internet connection. The cloud-based solution allows employees to work remotely, improving flexibility and collaboration.

- Improved Security: Most web-based QMS solutions offer robust security measures, including encryption, access controls, and data backups, ensuring the protection of sensitive information.

- Reduced Costs: Cloud-based QMS eliminates the need for on-premises infrastructure, reducing hardware, maintenance, and IT support costs associated with traditional on-premise QMS software systems.

- Automatic Software Updates: Cloud-based QMS providers handle software updates and maintenance, ensuring that users always have access to the latest features and security patches without the need for manual intervention.

- Faster Implementation: Online cloud-based QMS solutions can be deployed quickly, often requiring minimal setup and configuration, allowing companies to start using the system promptly.

- Scalability: Cloud-based QMS software offers scalability to accommodate the changing needs of companies, allowing for seamless expansion or downsizing of users, storage, and capabilities as business requirements evolve.

Cloud-based QMS solutions offer greater flexibility, scalability, and accessibility, along with improved security and cost-effectiveness. Companies are no longer limited to on-premise QMS software solutions and can now leverage the benefits of cloud-based QMS software.

When is the Right Time to Consider a QMS Software?

QMS software can be considered at any time, even when starting a company. Implementing QMS software from the beginning saves time and effort as it establishes robust quality management processes early on.

Companies often implement an eQMS once they have established or are actively developing their quality management system and related documentation. Although there is no perfect timing for implementation, the earlier a company implements an eQMS, the greater the benefits it can gain.

Some situations and challenges indicate the necessity for companies to adopt an eQMS. These include the need to enhance communication, automate QMS processes, improve compliance efforts, improve visibility into quality data, pursue scalability, and more.

How to Choose a Quality Management Software?

The main steps to choosing quality management software are mentioned below.

- Assess Your Requirements: Evaluate the company’s quality management needs and objectives, considering factors such as regulatory compliance requirements and process requirements.

- Research and Compare QMS Software Vendors: Research multiple QMS software vendors, comparing features, pricing, customer reviews, and industry reputation to identify potential candidates.

- Select Relevant QMS Software Vendors: Pick out QMS software vendors whose offerings align closely with the company’s requirements and objectives, ensuring vendors have a proven track record in the industry.

- Get Demos and Have Meetings: Request demonstrations and schedule meetings with selected vendors to gain a deeper understanding of their software’s capabilities and how it can address specific needs.

- Consider Getting a Trial: Explore the possibility of obtaining a trial period from the vendors under consideration, allowing employees to test the software in a real-world setting.

- Shortlist QMS Software Vendors: Create a shortlist of the most promising QMS software vendors based on their presentations, feedback from demos, and alignment with the company’s needs.

- Get Demonstration of Specific Use Cases: Ask shortlisted vendors to provide demonstrations focused on specific use cases relevant to the company, ensuring their software can effectively address particular challenges.

- Negotiate With Shortlisted QMS Providers: Engage in negotiations with the shortlisted QMS providers to discuss pricing, licensing terms, support services, any other add-ons, and any customization options required.

- Make Final Decision: Make a final decision based on a comprehensive evaluation of each vendor’s offerings, taking into account factors such as functionality, cost-effectiveness, vendor support, and potential for long-term value.

Simplify the decision-making process of choosing a QMS software with our QMS Software Comparison Template.

Use the template to conduct a thorough comparison of various QMS software solutions, evaluating vendor features, functionalities, pricing structures, and more. The comprehensive side-by-side comparison helps you understand exactly what each QMS software and vendor has to offer.

What are the Best QMS Software Solutions for Life Sciences?

The best QMS software solutions for Life Science companies are as follows.

- SimplerQMS: SimplerQMS is a QMS software designed for companies in the Life Science industry, including medical devices, pharmaceuticals, laboratories, and biotechnology. Renowned for its comprehensive support of all Life Science QMS processes, extensive module offering, and ease of use, it stands as an effective QMS software solution for these industries. SimplerQMS is integrated with Microsoft Office and requires no additional validation from customers since it is fully validated according to GAMP5.

- Qualio: Qualio is a QMS software for Life Science companies that is tailored specifically for growing companies and startups. Qualio is known for its native web-based document editor, which facilitates transparent document management processes.

- MasterControl: MasterControl is a QMS software designed for various Life Sciences, especially large enterprises. MasterControl is renowned for its comprehensive document control and quality management solutions that are compliant with FDA 21 CFR Part 11 regulation.

- TrackWise: TrackWise is a QMS software designed for industries such as pharmaceuticals, biotechnology, medical devices, diagnostics, and food and beverage. TrackWise is known for its AI-augmented decision-making capabilities, enabling a shift from reactive to proactive quality management.

- Ideagen Quality Management: Ideagen Quality Management, formerly Q-Pulse, is a QMS software designed for various industries, including Life Sciences. Ideagen Quality Management stands out for its extensive array of QMS modules and its utilization of Microsoft Office applications for document editing, along with offering e-learning capabilities.

- Greenlight Guru: Greenlight Guru is a cloud-based QMS software designed for the MedTech industry. Greenlight Guru is renowned for its requirements management and traceability matrix capabilities, and native document editing features, which simplify workflows with in-app editing.

- Dot Compliance: Dot Compliance is a QMS software designed for Life Sciences companies. Dot Compliance is renowned for its AI assistant, Dottie AI, which automatically scans vast amounts of text and diverse data, identifies correlations, and provides ongoing, up-to-date AI insights.

- QT9: QT9 is a web-based eQMS that provides a quality management solution for various industries, including medical devices, pharmaceuticals, chemicals, manufacturing, food and beverage, cosmetics, and more. QT9 QMS is renowned for its extensive range of over 23 built-in QMS modules.

- Scilife: Scilife is a QMS software designed for the Life Sciences industry. Scilife is known for its comprehensive QMS modules. The software is validated according to GAMP 5 on the Amazon Web Services (AWS) platform.

Ready to Learn More?

To learn how your life science company can make the most of SimplerQMS’s QMS solution, book a free demo.